Commissioning is a necessary step in the manufacturing process. It’s basically testing equipment to make sure that everything is functioning and behaving in the way that it’s supposed to behave.

Commissioning is usually one of the very last steps in machine manufacturing. Obviously, you want to ensure that everything is working properly before running production so their aren’t any unexpected hiccups. It’s better to prevent errors than try and recover from errors. However, since commissioning takes place so late into the process, any issues that need to be addressed significantly increase costs and put strain on deadlines.

Ideally, you would be able work out any kinks early into the process to avoid backtracking and wasting time and money fixing problems further down the line.

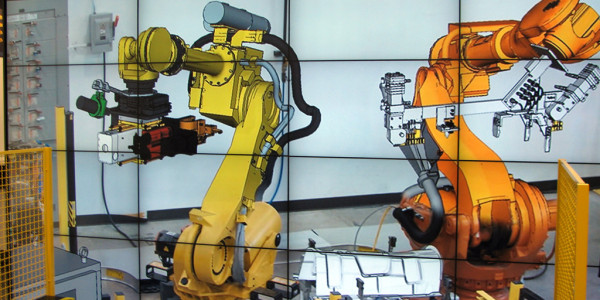

Virtual Commissioning (also known as emulation for logic validation) is running checks for physical components in a virtual setting. It’s simulating the actual automated motion of hardware with software to detect any problems that might occur in the process.

The advantage of virtual commissioning is that it can be done simultaneously with, or even before, hardware installation. This means that advancing to production is a smooth transition with minimal complications. Being able to make this transition translates to increased efficiency.

Virtual commissioning is just another example of how software and computers are indispensable to manufacturing. Computing is what makes Indradrive systems possible. Without software the control couldn’t communicate with the drive, which in turn would be unable to direct the servos, which means that nothing would get done.

We are well past the days when software and computers weren’t necessary for production and manufacturing. Practically every system out there is run with software. But many systems aren’t just being run by software; software is an integral part of the process. That’s the case with virtual commissioning, and the basis of the Industrial Internet of Things.