Renaissance literally translates from French as “re-birth”. When something is reborn there’s the implication of a positive change. It may be a change from bad to good, or from good to better. A renaissance heralds a new and favorable chapter of something. Even if you slept through history class you are probably aware of the Italian Renaissance. It marked a revisiting of classical forms and a reevaluation of the arts. Some of the world’s most recognizable paintings and sculptures come from the period.

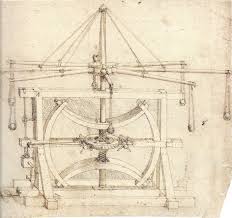

Leonardo da Vinci might be one of the most recognizable figures from the Italian Renaissance. He’s most known for works like Mona Lisa and The Last Supper but was also an engineer and inventor. He had designs for hydraulic pumps, reversible crank mechanisms, flying machines, and even a mechanical knight! Da Vinci would have undoubtedly loved to see the machinery that exists today and to witness the renaissance in US manufacturing.

The mid 20th-century was a golden age for manufacturing in the US. In the mid-1860s, American inventors came up with a wealth of new ideas for automating industry, and factories developed in the Northeastern states. As World War I ramped up, the assembly line revolutionized manufacturing. As World War II increased the need for manufactured goods, manufacturing boomed in America and factories spread across the Steel Belt. It was against this backdrop of exciting innovation that Indramat developed.

US manufacturing started to decline in the 1980’s when companies began off-shoring production. It was a cheaper option that fed the American consumer’s desire for cheaper goods.

However, off-shoring isn’t as economically advantageous as it was 3o years ago. Wages are increasing overseas and energy costs are rising as well. US manufacturing jobs are actually increasing rather than decreasing now.

There’s a push for advancements in manufacturing technologies through government funding. In 2013 the Obama administration announced a plan to establish 45 Manufacturing Innovation Institutes (hubs consisting of universities, leaders in manufacturing, and the federal government working together) across the US. The new Workforce Innovation and Opportunity Act, a new law supporting more focused training and apprenticeships, is the first update of government jobs legislation in 15 years.

The interest, funding, and technology involved with US manufacturing at the moment really do make this a renaissance for the industry. Who knows what lasting works will come in the near future?!