The next revolution in manufacturing is incredibly close at hand. People are making grand predictions about the Internet of Things and all of the amazing changes that will inevitably result from something as huge as interconnectivity between machinery and computers in the manufacturing industry.

People have every right to get excited about the IoT and IoT technologies. The Internet of Things will change how manufacturing is done, and it’s worth plenty of thought and consideration. But it doesn’t always take something as monumental as the Internet of Things to have a big impact on manufacturing. Sometimes even small changes can have drastic effects.

A grain of sand can tip the scale, and a ship that’s off by a couple of degrees can end up on the wrong continent. A group of Swedish researchers could make some huge contributions to manufacturing through subtle improvements to robotic movements.

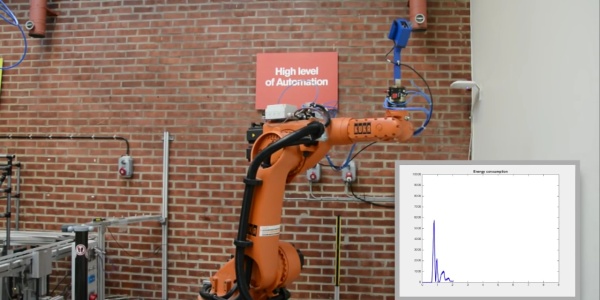

The team from Chalmer’s University of Technology is doing research as part of the European Union’s AREUS Project (Automaton and Robotics for European Sustainable Manufacturing). The researchers recognized that many robotic arms are not moving as efficiently as they potentially could, so they came up with an algorithm to optimize the acceleration and deceleration of the robots.

The changes made to the robots’ movement are slight. They are hardly perceptible to the human eye, and if you don’t work around robotic arms everyday, you probably wouldn’t even notice that the movement was any different at all. However the subtle trajectory changes reduced energy consumption by nearly one-third. Reduced energy consumption increases machine efficiency, and the benefits increase exponentially over time.

An optimization algorithm seems hardly worth mentioning when compared to something like the Internet of Things, but a 30-35 percent reduction in energy use is certainly a big deal when it comes to manufacturing. It just goes to show that minor changes can have a big impact.