When you’re reveling in your golden years, you might look back at your life and think about the legacy you’re leaving behind. Your legacy will include all of your most glorious triumphs, your meaningful accomplishments, and the contributions you’ve made to society and to the lives of the people you’ve known.

The word “legacy”, when used in the context of manufacturing, doesn’t quite have the same romance to it. A legacy system is one that is technically outdated. The system has been superseded by another, and the components are no longer made.

People often use the term “legacy” to imply that a system’s software or hardware are antiquated and in need of replacement, but that’s not always true. While there may be newer versions of the hardware or software, legacy systems don’t necessarily need to be replaced.

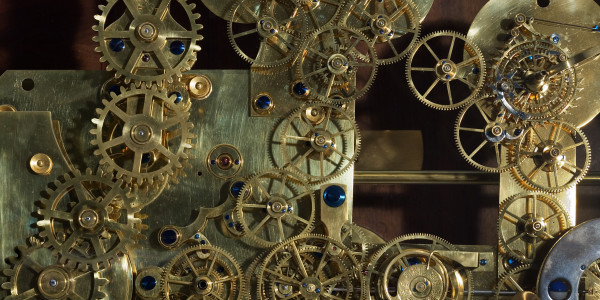

Indramat’s legacy

Indramat products are incredibly well-built, which is why many legacy components still work perfectly after decades of use.

Doing a complete overhaul of your system just because it’s old isn’t always feasible, and in many cases not even necessary. The costs involved with purchasing new software and machinery compounded with downtime and learning a new system may not be worth the marginal improvements you may see with updating your current system.

Legacy parts may not be manufactured anymore, but that doesn’t mean they’re unavailable. Indramat provides amazing factory support, including warrantied rebuilds. We also have the largest stock of Indramat replacement units in the country.

People have a habit of sinking money into something just because it’s new. But just because something is the latest doesn’t always mean it’s the greatest. There’s a reason people say, “They don’t make ’em like they used to.” Don’t think of legacy as being a bad thing. Take pride in the fact that your machinery has been running strong for years, and know that with the proper maintenance it will continue to run for years to come.